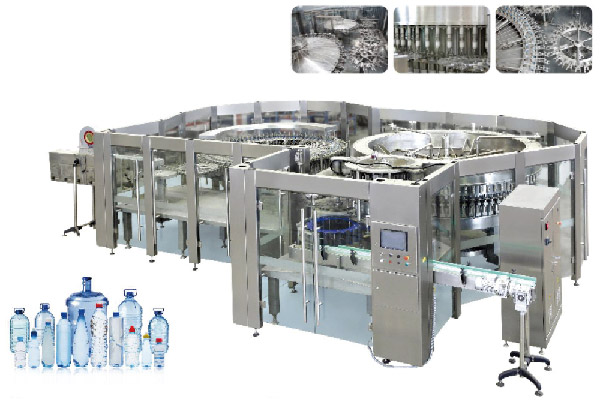

Bottled Drinking Water Filling Line

Bottled Water Filling Line fully automated system. It integrates washing, filling and capping in one compact unit. With advanced technology, the line ensures consistent quality, hygiene, and high-speed operation, capable of handling various bottle sizes and materials. Ideal for both small and large-scale production, this system guarantees reliability, meeting international standards for food safety and environmental sustainability, while minimizing labor costs and maximizing production efficiency.

Equipment Type : Automatic

Capacity:2000-42000 BPH

Bottle Capacity Range: 200ml – 2000ml

Equipment Material:SUS304/316 food grade stainless steel

Bottle Type: PET round or square bottle, Bottle diameter 50-115mm, Bottleheight 160-320mm

Applicable Beverage Types:Purified water/ Mineral water/Soda water/Sparkling water/ Functional drinks

Tel: +86 371-86582811

Mob & Whatsapp: +86 15239453015

Email: info@hadofmachinery.com

- Working Process

- Parameter

- Features

- Details

- Our Service

1. Flushing And Disinfection

Will be

treated with ultraviolet or high-temperature steam disinfection

system to remove the presence of bacteria or microorganisms.

2. Filling

The automatic filling machine accurately fills water into

the bottle according to the set capacity (such as 500ml, 1L, etc.)

to ensure the accuracy and speed of filling without losing

quality.

3. Capping

The

automatic capping system correctly matches the bottle cap with the

bottle to ensure that the bottle cap is tightly closed and the

water quality in the bottle is not contaminated.

| Model | Washing Nos | Filling Nos | Capping Nos | Capacity | Measurement | Power |

| HDF8/8/3 | 8 | 8 | 3 | 2000BPH | 2000x1500x2500mm | 1.5kw |

| HDF14/12/5 | 14 | 12 | 5 | 5500BPH | 2360x1770x2700mm | 2.0kw |

| HDF16/16/5 | 16 | 16 | 5 | 8000BPH | 2850x2150x2750mm | 2.2kw |

| HDF24/14/8 | 24 | 24 | 8 | 12000BPH | 2880x2180x2750mm | 2.2kw |

| HDF32/32/8 | 32 | 32 | 8 | 15000BPH | 3380x2580x2750mm | 3.0kw |

| HDF40/40/10 | 40 | 40 | 10 | 18000BPH | 4430x3280x2750mm | 7.5kw |

| HDF50/50/15 | 50 | 50 | 15 | 24000BPH | 4720x3550x2750mm | 7 .5kw |

| HDF60/60/15 | 60 | 60 | 15 | 30000BPH | 6000x5450x2750mm | 11kw |

| HDF72/72/18 | 72 | 72 | 18 | 36000BPH | 6500x4680x2750mm | 15kw |

| HDF80/80/22 | 80 | 80 | 22 | 42000BPH | 7800x6380x2750mm | 19kw |

1. Fully Automatic Integration

Our filling

line integrates multiple functions such as bottle washing, filling, and

capping. It is easy to operate, saves space, and provides you with a

one-stop solution.

2. Flexible Production Capacity

Supports adjustment of different capacities, bottle shapes, and

production speeds, and adapts to small-batch customized production and

large-scale continuous production.

3. Energy Saving

Our filling line design focuses on reducing water and electricity

consumption, helping you save production costs and enhance the

sustainable development capabilities of the enterprise.

4. Stability And Durability

The equipment uses high-quality materials and precise

manufacturing processes, with a long service life and a low failure

rate. The filling line can operate stably for a long time and is easy to

maintain.

5. International Standards

The equipment complies with international standards such as ISO

and CE, meets the quality certification requirements of different

countries and regions, and provides global technical support to ensure

equipment maintenance and service.

6. Customized Services

We provide tailor-made bottled water filling line solutions

according to your specific needs, supporting flexible configuration of

various bottle shapes, capacities and production scales to ensure a

perfect fit for your production requirements.

1. Washing Part

1.The air conveying

device that enters the bottle channel is directly connected to the

bottle dial

2.All 304/316 stainless steel rinse heads, water

spray style inject design, more save water consumption and more

clean.

3.304/316 Stainless steel Gripper with plastic pad, ensure

minimal bottle crash during washing.

4.304/316 stainless steel

washing pump make the machine more durable.

2. Filling Parts

1.304/316 Stainless

steel high precision filling nozzle

2.Filling volume adjustable

in fine rank, same liquid level after filling

3.All 304/316

stainless steel contact parts & liquid tank, fine polish, no death

corner, easy to clean

4.304/316 stainless steel filling pump

5.Efficient

spray nozzle rinse thoroughly and save water for flushing

3. Capping Parts

1.Place and capping

system, electromagnetic capping heads, with burden discharge function,

make sure minimum bottle crash during capping

2.All 304/316

stainless steel construction

3.No bottle no capping

4.Automatic

stop when lack of bottle

5.Capping effect is stable and reliable,

Defective rate ≤0.2%

-

Complete solution

Provide whole plant design engineering from product technology

to water treatment, pretreatment, bottle blowing, filling,

capping, coding, labeling, conveying, packaging, intelligent

warehousing, etc. according to customer needs. -

Innovative technology

We efficiently combine the latest industry technologies to

develop and transform equipment to improve production capacity,

helping you stay at the forefront of the industry and gain

market competitiveness. -

Quality and Testing

Hadof has invested heavily in cutting-edge R&D, advanced

processing and testing equipment. Digital projector,Endoscope

mirror,Portable spectrum Analyzer,Ultrasonic flaw

detector,Metallurgical Microscope and so on. -

Customized Services

We will customize equipment and solutions based on your site,

budget and other specific needs to ensure that each device

perfectly meets your needs and helps you grow.

Global Markets As a renowned food and beverage

manufacturer, we operate in global markets and have a full system in

place to efficiently deliver our products to customers around the

world. Our commitment to quality and safety is reflected in the

certifications we adhere to, which ensure compliance with US and

European standards.

In order to better serve our customers, we

have established branches and representative offices in strategic

locations around the world. Our operations cover Russia, USA,

Indonesia, Chile, Colombia and Algeria.