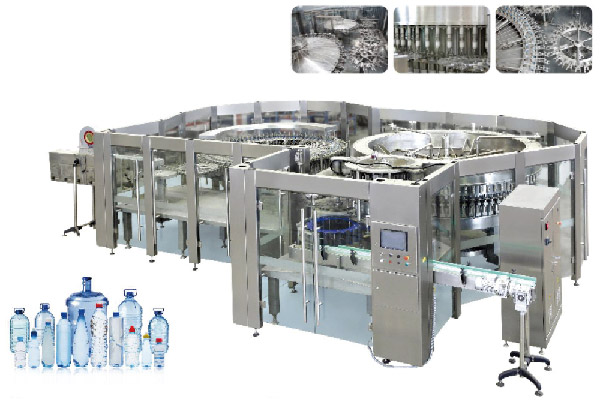

Линия заполнения питьевой воды в бутылках

Линия заполнения бутилированной воды Полностью автоматизированная система. Он интегрирует стирку, Заполнение и укрытие в одном компактном блоке. С передовыми технологиями, Линия обеспечивает постоянное качество, гигиена, и высокоскоростная работа, Способен обрабатывать различные размеры бутылок и материалы. Идеально подходит как для малого, так и для крупномасштабного производства, Эта система гарантирует надежность, соответствие международным стандартам безопасности пищевых продуктов и экологической устойчивости, При минимизации затрат на рабочую силу и максимизации эффективности производства.

Тип оборудования : Автоматический

Емкость:2000-42000 Внедл

Диапазон емкости бутылки: 200мл – 2000мл

Материал оборудования:SUS304/316 Пищевой класс из нержавеющей стали.

Тип бутылки: Домашний питомец или квадратная бутылка, Диаметр бутылки 50-115 мм, BottleHeight 160-320 мм

Применимые типы напитков:Очищенная вода/Минеральная вода/Газированная вода/Газированная вода/Функциональные напитки

Тел: +86 371-86582811

Моб & WhatsApp: +86 15239453015

Электронная почта: info@hadofmachinery.com

- Рабочий процесс

- Параметр

- Функции

- Подробности

- Наш сервис

1. Промывка и дезинфекция

Будет

обработаны ультрафиолетовой или высокотемпературной паровой дезинфекцией

система для удаления бактерий и микроорганизмов.

2. Наполнение

Автоматическая разливочная машина точно наполняет воду в

бутыль согласно установленной вместимости (такие как 500 мл, 1Л, и т. д.)

обеспечить точность и скорость наполнения без потери

качество.

3. Задержка

The

автоматическая система укупорки правильно совмещает крышку бутылки с

бутылку, чтобы убедиться, что крышка бутылки плотно закрыта и

качество воды в бутылке не загрязнено.

| Модель | Мыть № | Заполнение № | Закрытие nos | Емкость | Измерение | Власть |

| HDF8/8/3 | 8 | 8 | 3 | 2000Внедл | 2000x1500x2500mm | 1.5кВт |

| HDF14/12/5 | 14 | 12 | 5 | 5500Внедл | 2360x1770x2700 мм | 2.0кВт |

| HDF15 / 16/5 | 16 | 16 | 5 | 8000Внедл | 2850х2150х2750мм | 2.2кВт |

| HDF24/14/8 | 24 | 24 | 8 | 12000Внедл | 2880х2180х2750мм | 2.2кВт |

| HDF32/32/8 | 32 | 32 | 8 | 15000Внедл | 3380х2580х2750мм | 3.0кВт |

| HDF40 / 40/10 | 40 | 40 | 10 | 18000Внедл | 4430х3280х2750мм | 7.5кВт |

| ХДФ50/50/15 | 50 | 50 | 15 | 24000Внедл | 4720х3550х2750мм | 7 .5кВт |

| HDF60/60/15 | 60 | 60 | 15 | 30000Внедл | 6000х5450х2750мм | 11кВт |

| HDF72/72/18 | 72 | 72 | 18 | 36000Внедл | 6500х4680х2750мм | 15кВт |

| ХДФ80/80/22 | 80 | 80 | 22 | 42000Внедл | 7800х6380х2750мм | 19кВт |

1. Полностью автоматическая интеграция

Наша начинка

линия объединяет несколько функций, таких как мытье бутылок, наполнение, и

задержка. Легко работать, спасает пространство, и предоставляет вам

универсальное решение.

2. Гибкая производственная мощность

Поддерживает настройку различных мощностей, формы бутылок, и

скорость производства, и адаптируется к мелкосерийному индивидуальному производству и

крупномасштабное непрерывное производство.

3. Энергетическая экономия

В конструкции нашей линии розлива основное внимание уделяется сокращению потребления воды и электроэнергии.

потребление, помогая вам сэкономить производственные затраты и повысить

возможности устойчивого развития предприятия.

4. Стабильность и долговечность

В оборудовании используются высококачественные материалы и точная

производственные процессы, с длительным сроком службы и низким уровнем отказов

ставка. Линия розлива может работать стабильно в течение длительного времени и проста в обслуживании.

поддерживать.

5. Международные стандарты

Оборудование соответствует международным стандартам, таким как ISO.

и CE, соответствует требованиям сертификации качества различных

страны и регионы, и предоставляет глобальную техническую поддержку для обеспечения

обслуживание и обслуживание оборудования.

6. Индивидуальные услуги

Мы предоставляем индивидуальные решения для линий розлива бутилированной воды.

в соответствии с вашими конкретными потребностями, поддержка гибкой настройки

различные формы бутылок, мощности и масштабы производства, обеспечивающие

идеально подходит для ваших производственных требований.

1. Мытья часть

1.Воздушная транспортировка

устройство, которое входит в канал бутылки, напрямую подключено к

бутылочный циферблат

2.Все 304/316 ополаскивание нержавеющей стали головы, вода

дизайн впрыска в стиле спрея, больше экономить потребление воды и многое другое

чистый.

3.304/316 Захватчик из нержавеющей стали с пластиковой прокладкой, гарантировать

минимальное разбивание бутылки во время мытья.

4.304/316 нержавеющая сталь

Стиральный насос делает машину более долговечной.

2. Заполняющие детали

1.304/316 Нержавеющая сталь

стальная высокоточная насадка для наполнения

2.Регулируемый объем наполнения

в хорошем звании, тот же уровень жидкости после заполнения

3.Все 304/316

контактные части из нержавеющей стали & жидкий бак, прекрасный лак, нет смерти

угол, Легко чистить

4.304/316 Наполнительный насос из нержавеющей стали

5.Эффективный

распылительную насадку тщательно промойте и сохраните воду для промывки

3. Закрытие деталей

1.Место и укупорка

система, Электромагнитные заглушки, с функцией сброса бремени,

следить за тем, чтобы бутылка не разбивалась во время укупоривания

2.Все 304/316

конструкция из нержавеющей стали

3.Нет бутылки, нет укупорки

4.Автоматический

остановиться, когда не хватает бутылки

5.Эффект ограничения стабилен и надежен,

Дефектная скорость ≤0,2%

-

Полное решение

Обеспечить проектирование всего завода, начиная с технологии продукта.

для очистки воды, предварительная обработка, Бутылка дует, наполнение,

задержка, кодирование, маркировка, передача, упаковка, разумный

складирование, и т. д.. в соответствии с потребностями клиента. -

Инновационные технологии

Мы эффективно сочетаем новейшие отраслевые технологии для

разрабатывать и трансформировать оборудование для повышения производственных мощностей,

помогая вам оставаться в авангарде отрасли и получать

рыночная конкурентоспособность. -

Качество и тестирование

HADOF инвестировал значительные средства в передовые R&Дюймовый, передовой

оборудование для обработки и испытаний. Цифровой проектор,Эндоскоп

зеркало,Портативный анализатор спектра,Ультразвуковой дефект

детектор,Металлургический микроскоп и так далее. -

Индивидуальные услуги

Мы будем настраивать оборудование и решения на основе вашего сайта,

бюджет и другие конкретные потребности, чтобы гарантировать, что каждое устройство

идеально отвечает вашим потребностям и помогает вам расти.

Глобальные рынки Как известная еда и напиток

производитель, мы работаем на мировых рынках и имеем полную систему в

место для эффективной доставки нашей продукции клиентам по всему миру

мир. Наша приверженность качеству и безопасности отражена в

сертификаты, которых мы придерживаемся, которые обеспечивают соответствие стандартам США и

Европейские стандарты.

Чтобы лучше обслуживать наших клиентов, мы

создали филиалы и представительства в стратегических

места по всему миру. Наши операции охватывают Россию, США,

Индонезия, Чили, Колумбия и Алжир.