This production line is primarily used for washing, filling, and sealing easy-open cans made of tinplate, aluminum alloy, and PET plastic. It features automatic lifting of stacked empty cans, automatic overturning, automatic washing, filling, and sealing capabilities. With a high production capacity, it is the optimal equipment for producing carbonated beverages such as Coca-Cola and Pepsi.

Colour:Silver Grey

Usage: Liquid filling & packing

Filling Volume: 300ml-2000ml

Desalination rate: ≥90%

Other voltages can be customized Filling accuracy is as high as 99.8%

Tel: +86 371-86582811

Mob & Whatsapp: +86 15239453015

Email: info@hadofmachinery.com

- Working Process

- Parameter

- Features

- Details

- Our Service

1.Can Feeding: Empty cans are delivered to the filling machine via a conveyor system and organized for filling.

2.Positioning and Cleaning (Optional): Cans are positioned under the filling nozzles, and some systems may clean the cans for hygiene purposes.

3.Liquid Filling: The filling nozzles dispense liquid into the cans, with precise control to ensure uniformity.

4.Foam or Gas Removal: If foam is generated, the system may remove it to maintain filling quality.

5.Sealing Preparation and Operation: After filling, lids are automatically placed on the cans and secured by rotating or pressing for an airtight seal.

6.Quality Inspection and Output: Sealed cans are inspected for leaks or defects, and qualified products are conveyed to the packaging area for further processing.

| Model | HDF 12-1 | HDF18-6 | HDF24-6 |

| Production Capacity (b/h) | 1000–2000 | 3000–6000 | 4000–9000 |

| Power (kw) | 0.75 | 3.7 | 3.7 |

| Weight (kg) | 1800 | 2500 | 3000 |

| Overall Dimensions (mm) | 1750×1140×1950 | 2320×1400×1900 | 2580×1675×1900 |

1. High Degree of Automation: Most machines have a high level of automation, reducing the need for manual intervention and thereby lowering labor costs.

2. Accurate Filling: Advanced filling technology ensures consistent fill volumes for each can, minimizing material waste.

3. Fast Sealing: Efficient sealing systems can complete the sealing process quickly, ensuring smooth operation of the production line.

4. Strong Adaptability: Capable of handling various types and sizes of cans to meet different product packaging needs.

5. Hygienic Design: Complies with food safety standards, using stainless steel and other easy-to-clean materials to ensure a hygienic production process.

6. Compact Structure: Has a compact design that takes up minimal space, suitable for production environments of different scales.

1.Filling Section The filling section uses 304/316 stainless steel high-precision filling nozzles and filling pumps, with all contact parts and liquid tanks finely polished for easy cleaning.

2. Sealing Section The sealing and capping system features an electromagnetic capping head with an unloading function to ensure minimal impact on the bottles during the capping process.

3. Reversible Device This machine has a flip device that is suitable for flipping the cooling or heating channels of the can.

4. Control System The control system utilizes PLC to automate the entire process of the three in one filling machine from bottle entry to bottle exit, and operates through a touch screen that displays production indicators and fault information.

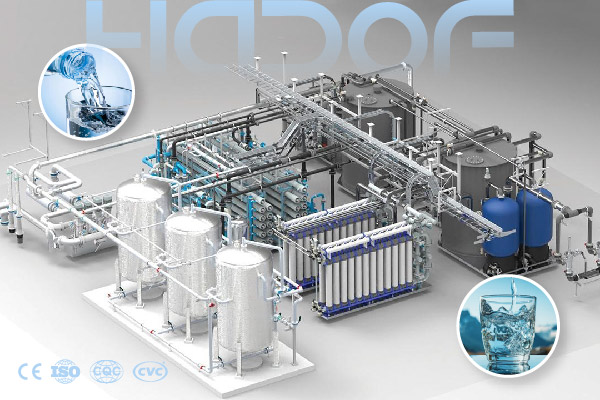

Complete solution

Provide whole plant design engineering from product technology to water treatment, pretreatment, bottle blowing, filling, capping, coding, labeling, conveying, packaging, intelligent warehousing, etc. according to customer needs.

Innovative technology

We efficiently combine the latest industry technologies to develop and transform equipment to improve production capacity, helping you stay at the forefront of the industry and gain market competitiveness.

Quality and Testing

Hadof has invested heavily in cutting-edge R&D, advanced processing and testing equipment. Digital projector,Endoscope mirror,Portable spectrum Analyzer,Ultrasonic flaw detector,Metallurgical Microscope and so on.

Customized Services

We will customize equipment and solutions based on your site, budget and other specific needs to ensure that each device perfectly meets your needs and helps you grow.

Global Markets As a renowned food and beverage manufacturer, we operate in global markets and have a full system in place to efficiently deliver our products to customers around the world. Our commitment to quality and safety is reflected in the certifications we adhere to, which ensure compliance with US and European standards.

In order to better serve our customers, we have established branches and representative offices in strategic locations around the world. Our operations cover Russia, USA, Indonesia, Chile, Colombia and Algeria.