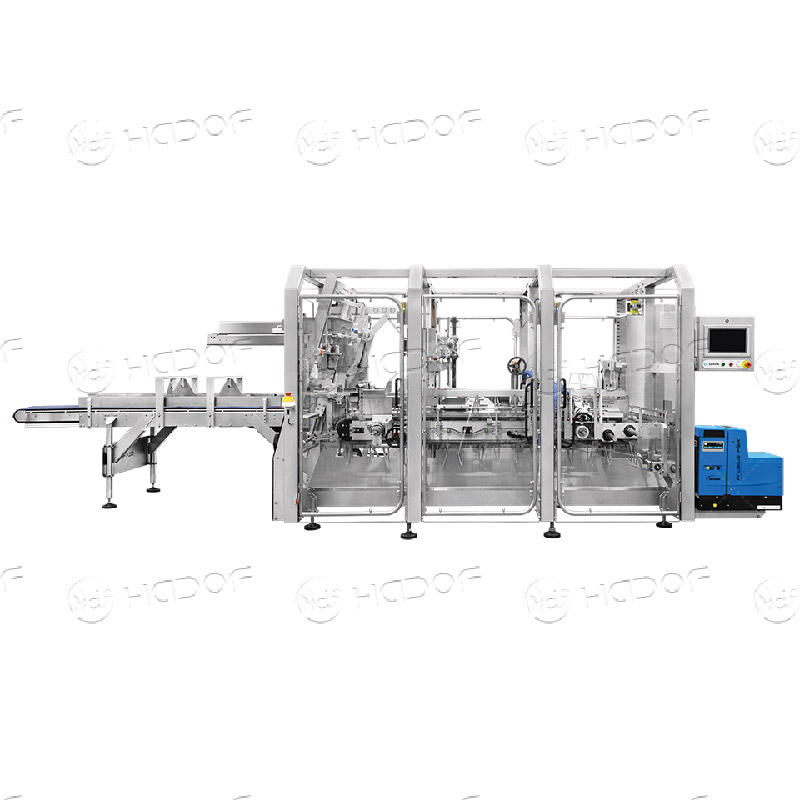

Carton Packing System

A carton packing system is an automated or semi-automated system designed to package products into cartons or boxes for storage, transportation, and retail display.

These systems are widely used in industries such as food and beverage, etc. They help improve packaging efficiency, ensure product protection, and reduce labor costs.

A carton packing system is a crucial component of modern manufacturing and logistics, ensuring that products are efficiently and securely packaged for distribution.

Tel: +86 371-86582811

Mob & Whatsapp: +86 15239453015

Email: info@hadofmachinery.com

- Working Process

- Parameter

- Features

- Details

- Our Service

Carton Erector: Automatically forms and shapes flat cardboard blanks into cartons. Ensures consistency in carton dimensions and shape. Often integrates with taping or gluing mechanisms for bottom sealing. Product Loading System: Places products into cartons using robotic arms, pick-and-place mechanisms, or manual insertion. It can handle single or multiple product placements in one cycle. Carton Sealing Machine: Seals the top and bottom of the carton using tape, glue, or hot-melt adhesives. Ensures cartons remain securely closed during transit. Labeling and Printing Systems: Applies bar code, branding, product details, or QR codes to cartons. Carton Inspection and Quality Control: Includes weight checks, bar code verification, and visual inspections. Ensures all cartons meet quality standards before shipping.

| Brand | Hadof |

| Size (L×W×H) | 1.2×1.3×1.7 m |

| Packing Speed | 300-420 box/hour |

| Weight | 600 kg |

| Power | 1 kw |

1.Automate repetitive tasks, increase efficiency, reduce labor costs and errors.

2.Ensures product protection, minimizes damage during handling and shipping.

3.Reduce material waste, optimize packaging material usage for cost-effectiveness.

1.Using 304 stainless steel process, it is not afraid of corrosion, high temperature resistance, long service life, easy to clean, and good sealing.

2.Fully automatic control system, microcomputer intelligent control, no need for manual supervision, saving labor costs, simple operation, simple maintenance.

3.Rich display instruments the equipment operation status can be detected at any time, with accurate measurement, stable performance and high safety.

Complete solution

Provide whole plant design engineering from product technology to water treatment, pretreatment, bottle blowing, filling, capping, coding, labeling, conveying, packaging, intelligent warehousing, etc. according to customer needs.

Innovative technology

We efficiently combine the latest industry technologies to develop and transform equipment to improve production capacity, helping you stay at the forefront of the industry and gain market competitiveness.

Quality and Testing

Hadof has invested heavily in cutting-edge R&D, advanced processing and testing equipment. Digital projector,Endoscope mirror,Portable spectrum Analyzer,Ultrasonic flaw detector,Metallurgical Microscope and so on.

Customized Services

We will customize equipment and solutions based on your site, budget and other specific needs to ensure that each device perfectly meets your needs and helps you grow.

Global Markets As a renowned food and beverage manufacturer, we operate in global markets and have a full system in place to efficiently deliver our products to customers around the world. Our commitment to quality and safety is reflected in the certifications we adhere to, which ensure compliance with US and European standards.

In order to better serve our customers, we have established branches and representative offices in strategic locations around the world. Our operations cover Russia, USA, Indonesia, Chile, Colombia and Algeria.