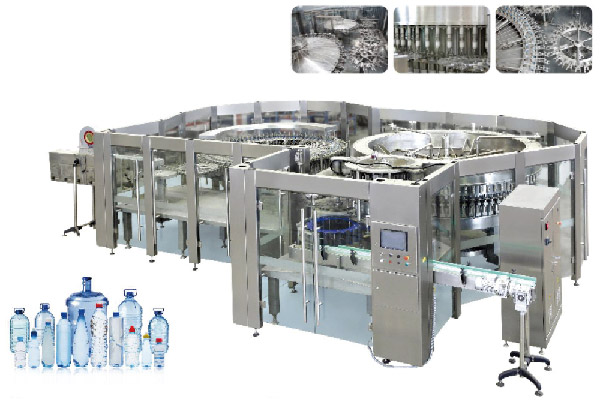

Abfülllinie für Trinkwasser in Flaschen

Vollautomatisches System zur Abfüllung von Flaschenwasser. Es integriert das Waschen, Abfüllen und Verschließen in einer kompakten Einheit. Mit fortschrittlicher Technologie, Die Linie gewährleistet eine gleichbleibende Qualität, Hygiene, und Hochgeschwindigkeitsbetrieb, Kann verschiedene Flaschengrößen und Materialien verarbeiten. Ideal für kleine und groß angelegte Produktion, Dieses System garantiert Zuverlässigkeit, Einhaltung internationaler Standards für Lebensmittelsicherheit und ökologische Nachhaltigkeit, bei gleichzeitiger Minimierung der Arbeitskosten und Maximierung der Produktionseffizienz.

Gerätetyp : Automatisch

Kapazität:2000-42000 BPH

Flaschenkapazitätsbereich: 200ml – 2000ml

Ausrüstungsmaterial:SUS304/316 Food Grade Edelstahl

Flaschenart: Runde oder eckige PET-Flasche, Flaschendurchmesser 50–115 mm, Flaschenhöhe 160–320 mm

Anwendbare Getränketypen:Purified water/ Mineral water/Soda water/Sparkling water/ Functional drinks

Tel: +86 371-86582811

Mob & WhatsApp: +86 15239453015

E-Mail: info@hadofmaachinery.com

- Arbeitsprozess

- Parameter

- Merkmale

- Details

- Unser Service

1. Spülung und Desinfektion

Will be

treated with ultraviolet or high-temperature steam disinfection

system to remove the presence of bacteria or microorganisms.

2. Füllung

The automatic filling machine accurately fills water into

the bottle according to the set capacity (wie 500 ml, 1L, usw.)

to ensure the accuracy and speed of filling without losing

quality.

3. Verschließen

The

automatic capping system correctly matches the bottle cap with the

bottle to ensure that the bottle cap is tightly closed and the

water quality in the bottle is not contaminated.

| Modell | Wasch-Nr | Füllungsnr | Kappen-Nr | Kapazität | Messung | Leistung |

| HDF8/8/3 | 8 | 8 | 3 | 2000BPH | 2000x1500x2500mm | 1.5KW |

| HDF14/12/5 | 14 | 12 | 5 | 5500BPH | 2360x1770x2700mm | 2.0KW |

| HDF16/16/5 | 16 | 16 | 5 | 8000BPH | 2850x2150x2750mm | 2.2KW |

| HDF24/14/8 | 24 | 24 | 8 | 12000BPH | 2880x2180x2750mm | 2.2KW |

| HDF32/32/8 | 32 | 32 | 8 | 15000BPH | 3380x2580x2750mm | 3.0KW |

| HDF40/40/10 | 40 | 40 | 10 | 18000BPH | 4430x3280x2750mm | 7.5KW |

| HDF50/50/15 | 50 | 50 | 15 | 24000BPH | 4720x3550x2750mm | 7 .5KW |

| HDF60/60/15 | 60 | 60 | 15 | 30000BPH | 6000x5450x2750mm | 11KW |

| HDF72/72/18 | 72 | 72 | 18 | 36000BPH | 6500x4680x2750mm | 15KW |

| HDF80/80/22 | 80 | 80 | 22 | 42000BPH | 7800x6380x2750mm | 19KW |

1. Vollautomatische Integration

Our filling

line integrates multiple functions such as bottle washing, Füllung, and

Capping. Es ist einfach zu bedienen, spart Platz, and provides you with a

one-stop solution.

2. Flexible Production Capacity

Supports adjustment of different capacities, bottle shapes, and

production speeds, and adapts to small-batch customized production and

large-scale continuous production.

3. Energieeinsparung

Our filling line design focuses on reducing water and electricity

consumption, helping you save production costs and enhance the

sustainable development capabilities of the enterprise.

4. Stabilität und Haltbarkeit

The equipment uses high-quality materials and precise

manufacturing processes, with a long service life and a low failure

rate. The filling line can operate stably for a long time and is easy to

maintain.

5. Internationale Standards

The equipment complies with international standards such as ISO

and CE, meets the quality certification requirements of different

countries and regions, and provides global technical support to ensure

equipment maintenance and service.

6. Benutzerdefinierte Dienste

We provide tailor-made bottled water filling line solutions

according to your specific needs, supporting flexible configuration of

various bottle shapes, capacities and production scales to ensure a

perfect fit for your production requirements.

1. Waschteil

1.The air conveying

device that enters the bottle channel is directly connected to the

bottle dial

2.All 304/316 Spülköpfe aus Edelstahl, Wasser

spray style inject design, more save water consumption and more

clean.

3.304/316 Greifer aus Edelstahl mit Kunststoffauflage, ensure

minimal bottle crash during washing.

4.304/316 stainless steel

washing pump make the machine more durable.

2. Füllteile

1.304/316 Stainless

steel high precision filling nozzle

2.Filling volume adjustable

in fine rank, same liquid level after filling

3.All 304/316

Kontaktteile aus Edelstahl & Flüssigkeitstank, feine Politur, no death

corner, leicht zu reinigen

4.304/316 stainless steel filling pump

5.Efficient

spray nozzle rinse thoroughly and save water for flushing

3. Abdeckteile

1.Place and capping

system, elektromagnetische Verschließköpfe, mit Entlastungsfunktion,

make sure minimum bottle crash during capping

2.All 304/316

stainless steel construction

3.No bottle no capping

4.Automatisch

stop when lack of bottle

5.Capping effect is stable and reliable,

Fehlerrate ≤0,2 %

-

Komplette Lösung

Provide whole plant design engineering from product technology

to water treatment, Vorbehandlung, Flaschenblasen, Füllung,

Capping, Codierung, Beschriftung, vermitteln, Verpackung, intelligent

warehousing, usw. nach Kundenbedürfnissen. -

Innovative Technologie

We efficiently combine the latest industry technologies to

develop and transform equipment to improve production capacity,

helping you stay at the forefront of the industry and gain

market competitiveness. -

Qualität und Test

Hadof hat stark in modernste R investiert r&D, advanced

processing and testing equipment. Digitaler Projektor,Endoscope

mirror,Tragbarer Spektrumanalysator,Ultrasonic flaw

detector,Metallurgisches Mikroskop und so weiter. -

Benutzerdefinierte Dienste

Wir werden Geräte und Lösungen basierend auf Ihrer Website anpassen,

budget and other specific needs to ensure that each device

perfectly meets your needs and helps you grow.

Globale Märkte As a renowned food and beverage

manufacturer, we operate in global markets and have a full system in

place to efficiently deliver our products to customers around the

world. Our commitment to quality and safety is reflected in the

certifications we adhere to, which ensure compliance with US and

European standards.

Um unseren Kunden besser zu bedienen, we

have established branches and representative offices in strategic

locations around the world. Unsere Operationen decken Russland ab, USA,

Indonesien, Chile, Kolumbien und Algerien.