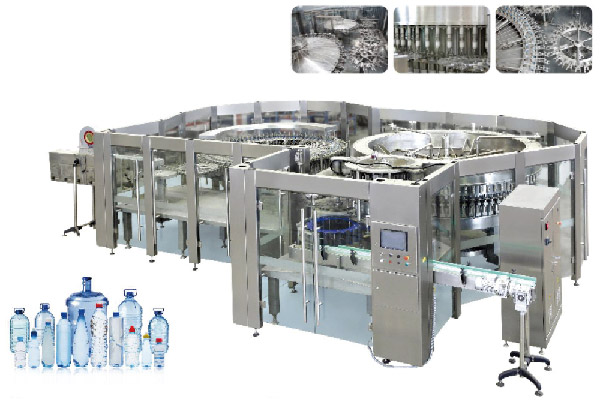

DAN -FILLING UND DAUSMACHRUNG

Farbe:Silbergrau

Verwendung: Flüssigkeitsfüllung & Verpackung

Füllvolumen: 300ML-2000ml

Entsalzungsrate: ≥ 90%

Andere Spannungen können angepasst werden, dass die Füllgenauigkeit so hoch ist wie 99.8%

Tel: +86 371-86582811

Mob & WhatsApp: +86 15239453015

E-Mail: info@hadofmaachinery.com

- Arbeitsprozess

- Parameter

- Merkmale

- Details

- Unser Service

1.Kann füttern: Leere Dosen werden über ein Fördersystem an die Füllmaschine geliefert und zum Füllen organisiert.

2.Positionierung und Reinigung (Optional): Dosen werden unter den Fülldüsen positioniert, und einige Systeme können die Dosen für Hygienezwecke reinigen.

3.Flüssigkeitsfüllung: Die Fülldüsen geben Flüssigkeit in die Dosen ein, mit präziser Kontrolle, um Gleichmäßigkeit zu gewährleisten.

4.Schaum- oder Gasentfernung: Wenn Schaum erzeugt wird, Das System kann es entfernen, um die Füllqualität aufrechtzuerhalten.

5.Versiegelungsvorbereitung und -betrieb: Nach dem Füllen, Deckel werden automatisch auf die Dosen platziert und durch Drehen oder Drücken eines luftdichten Siegels befestigt.

6.Qualitätsinspektion und Ausgabe: Versiegelte Dosen werden auf Lecks oder Mängel inspiziert, und qualifizierte Produkte werden zur weiteren Verarbeitung an den Verpackungsbereich übertragen.

| Modell | HDF 12-1 | HDF18-6 | HDF24-6 |

| Produktionskapazität (b/h) | 1000–2000 | 3000–6000 | 4000–9000 |

| Leistung (KW) | 0.75 | 3.7 | 3.7 |

| Gewicht (kg) | 1800 | 2500 | 3000 |

| Gesamtabmessungen (mm) | 1750× 1140 × 1950 | 2320× 1400 × 1900 | 2580× 1675 × 1900 |

1. Hoher Automatisierungsgrad: Die meisten Maschinen haben ein hohes Maß an Automatisierung, Reduzierung des Bedarfs an manueller Intervention und damit die Senkung der Arbeitskosten.

2. Genaue Füllung: Die fortschrittliche Fülltechnologie sorgt für eine konsistente Füllvolumina für jede Dose, Minimierung von Materialabfällen.

3. Schnelle Versiegelung: Effiziente Versiegelungssysteme können den Versiegelungsvorgang schnell abschließen, Gewährleistung eines reibungslosen Betriebs der Produktionslinie.

4. Starke Anpassungsfähigkeit: In der Lage, verschiedene Arten und Größen von Dosen umzugehen, um unterschiedliche Produktverpackungsanforderungen zu erfüllen.

5. Hygienisches Design: Entspricht den Lebensmittelsicherheitsstandards, Verwenden von Edelstahl und anderen einfach zu reduzierenden Materialien, um einen hygienischen Produktionsprozess zu gewährleisten.

6. Kompaktstruktur: Hat ein kompaktes Design, das minimalen Platz einnimmt, Geeignet für Produktionsumgebungen unterschiedlicher Skalen.

1.Füllabschnitt Der Füllabschnitt verwendet verwendet 304/316 Edelstahl hohe Präzisionsdüsen und Füllpumpen, Mit allen Kontaktteilen und flüssigen Panzern fein poliert für die einfache Reinigung.

2. Versiegelungsabschnitt Das Versiegelungs- und Kappensystem verfügt über einen elektromagnetischen Kackkopf mit einer Entlastungsfunktion, um einen minimalen Einfluss auf die Flaschen während des Verschleierungsprozesses zu gewährleisten.

3. Reversibler Gerät Diese Maschine verfügt über ein Flip -Gerät, das zum Umdrehen der Kühl- oder Heizkanäle der Dose geeignet ist.

4. Steuerungssystem Das Steuerungssystem verwendet SPS, um den gesamten Prozess der drei in einer Füllmaschine vom Flascheneintritt bis zur Flaschenausgang zu automatisieren, und arbeitet über einen Touchscreen, der Produktionsindikatoren und Fehlerinformationen anzeigt.

Komplette Lösung

Bereitstellung des gesamten Anlagendesign -Engineering von Produkttechnologie bis zur Wasserbehandlung, Vorbehandlung, Flaschenblasen, Füllung, Capping, Codierung, Beschriftung, vermitteln, Verpackung, intelligente Lagerhaltung, usw. nach Kundenbedürfnissen.

Innovative Technologie

Wir kombinieren effizient die neuesten Branchentechnologien, um Geräte zu entwickeln und zu transformieren, um die Produktionskapazität zu verbessern, Helfen Sie dabei.

Qualität und Test

Hadof hat stark in modernste R investiert r&D, Erweiterte Verarbeitungs- und Testgeräte. Digitaler Projektor,Endoskopspiegel,Tragbarer Spektrumanalysator,Ultraschallfehlerdetektor,Metallurgisches Mikroskop und so weiter.

Benutzerdefinierte Dienste

Wir werden Geräte und Lösungen basierend auf Ihrer Website anpassen, Budget und andere spezifische Bedürfnisse, um sicherzustellen, dass jedes Gerät Ihren Anforderungen perfekt entspricht und Ihnen hilft, zu wachsen.

Globale Märkte Als renommierter Hersteller von Lebensmitteln und Getränken, Wir arbeiten in globalen Märkten und haben ein volles System, um unsere Produkte effizient an Kunden auf der ganzen Welt zu liefern. Unser Engagement für Qualität und Sicherheit spiegelt sich in den Zertifizierungen wider, an die wir festhalten, die die Einhaltung der US- und europäischen Standards gewährleisten.

Um unseren Kunden besser zu bedienen, Wir haben Zweige und repräsentative Büros an strategischen Orten auf der ganzen Welt etabliert. Unsere Operationen decken Russland ab, USA, Indonesien, Chile, Kolumbien und Algerien.