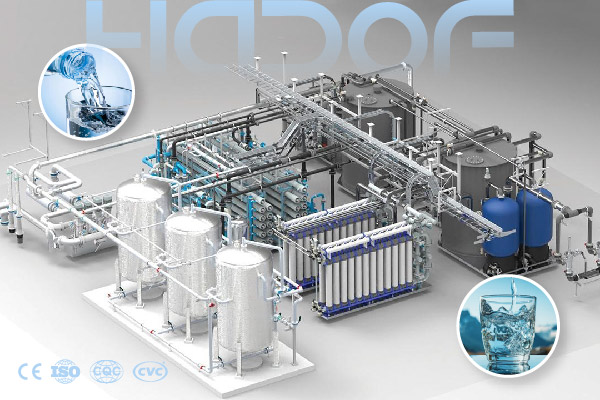

Esta linha de produção é usada principalmente para lavar, enchimento, e selando latas fáceis de abertura feitas de lata, liga de alumínio, e plástico para animais de estimação. Possui levantamento automático de latas vazias empilhadas, capotamento automático, lavagem automática, enchimento, e capacidades de vedação. Com alta capacidade de produção, É o equipamento ideal para produzir bebidas carbonatadas, como Coca-Cola e Pepsi.

Cor:Cinza prateado

Uso: Recheio de líquido & embalagem

Volume de preenchimento: 300ML-2000ml

Taxa de dessalinização: ≥90%

Outras tensões podem ser personalizadas de precisão de preenchimento é tão alta quanto 99.8%

Tel: +86 371-86582811

MOB & Whatsapp: +86 15239453015

E-mail: info@hadofmachinery.com

- Processo de trabalho

- Parâmetro

- Características

- Detalhes

- Nosso serviço

1.Pode alimentar: Latas vazias são entregues na máquina de enchimento por meio de um sistema de transportadores e organizadas para encher.

2.Posicionamento e limpeza (Opcional): Latas estão posicionadas sob os bicos de enchimento, e alguns sistemas podem limpar as latas para fins de higiene.

3.Recheio de líquido: Os bicos de enchimento dispensam o líquido nas latas, com controle preciso para garantir a uniformidade.

4.Remoção de espuma ou gás: Se a espuma for gerada, O sistema pode removê -lo para manter a qualidade do preenchimento.

5.Preparação e operação de vedação: Depois de encher, As tampas são colocadas automaticamente nas latas e protegidas girando ou pressionando para um selo hermético.

6.Inspeção e saída de qualidade: Latas seladas são inspecionadas quanto a vazamentos ou defeitos, e produtos qualificados são transportados para a área de embalagem para processamento adicional.

| Modelo | HDF 12-1 | HDF18-6 | HDF24-6 |

| Capacidade de produção (b/h) | 1000–2000 | 3000–6000 | 4000–9000 |

| Poder (KW) | 0.75 | 3.7 | 3.7 |

| Peso (kg) | 1800 | 2500 | 3000 |

| Dimensões gerais (mm) | 1750× 1140 × 1950 | 2320× 1400 × 1900 | 2580× 1675 × 1900 |

1. Alto grau de automação: A maioria das máquinas tem um alto nível de automação, reduzindo a necessidade de intervenção manual e, assim, diminuindo os custos de mão -de -obra.

2. Preenchimento preciso: A tecnologia de enchimento avançada garante volumes de preenchimento consistentes para cada uma delas, minimizar o desperdício de material.

3. Vedação rápida: Sistemas de vedação eficientes podem concluir o processo de vedação rapidamente, garantir uma operação suave da linha de produção.

4. Forte adaptabilidade: Capaz de lidar com vários tipos e tamanhos de latas para atender às diferentes necessidades de embalagem de produtos.

5. Design higiênico: Está em conformidade com os padrões de segurança alimentar, Usando aço inoxidável e outros materiais fáceis de limpar para garantir um processo de produção higiênico.

6. Estrutura compacta: Tem um design compacto que ocupa um espaço mínimo, Adequado para ambientes de produção de diferentes escalas.

1.Seção de enchimento A seção de enchimento usa 304/316 bocais de enchimento de alta precisão de aço inoxidável e bombas de enchimento, Com todas as peças de contato e tanques líquidos, finamente polidos para facilitar a limpeza.

2. Seção de vedação O sistema de vedação e captura apresenta uma cabeça de capeamento eletromagnética com uma função de descarregamento para garantir um impacto mínimo nas garrafas durante o processo de captura.

3. Dispositivo reversível Esta máquina possui um dispositivo flip adequado para lançar os canais de resfriamento ou aquecimento da lata.

4. Sistema de controle O sistema de controle utiliza o PLC para automatizar todo o processo dos três em uma máquina de enchimento, desde a entrada do frasco até a saída da garrafa, e opera através de uma tela de toque que exibe indicadores de produção e informações de falha.

Solução completa

Fornecer engenharia de projeto de plantas inteiras, desde a tecnologia do produto até o tratamento de água, pré -tratamento, Garrafa soprando, enchimento, Captura, codificação, rotulagem, transmitir, embalagem, armazenamento inteligente, etc.. De acordo com as necessidades do cliente.

Tecnologia inovadora

Combinamos com eficiência as mais recentes tecnologias da indústria para desenvolver e transformar equipamentos para melhorar a capacidade de produção, Ajudando você a permanecer na vanguarda da indústria e a obter competitividade no mercado.

Qualidade e teste

Hadof investiu pesadamente em r de ponta&D, Equipamento avançado de processamento e teste. Projetor digital,Espelho do endoscópio,Analisador de espectro portátil,Detector de falhas ultrassônicas,Microscópio metalúrgico e assim por diante.

Serviços personalizados

Personalizaremos equipamentos e soluções com base em seu site, Orçamento e outras necessidades específicas para garantir que cada dispositivo atenda perfeitamente às suas necessidades e ajude você a crescer.

Mercados globais Como um fabricante de alimentos e bebidas de renome, Operamos nos mercados globais e temos um sistema completo para entregar com eficiência nossos produtos a clientes em todo o mundo. Nosso compromisso com a qualidade e a segurança se reflete nas certificações que seguimos, que garantem conformidade conosco e padrões europeus.

Para melhor atender nossos clientes, Estabelecemos filiais e escritórios representativos em locais estratégicos em todo o mundo. Nossas operações cobrem a Rússia, EUA, Indonésia, Chile, Colômbia e Argélia.